Cement Screw Conveyors

In over four decades the ES-type Screw Conveyor has become a synonym for cement feeding and conveying in concrete batching plants all over the world. In this period WAM has supplied more than half a million units. Today it is hardly possible to find a batching plant manufacturer anywhere in the world who would not appreciate the unrivalled technical features and quality of the ES.

Description

As a specialized version of the modular TU Screw Conveyor System, ES Screw Conveyors and Feeders are manufactured from carbon steel with suitable surface finishing and powder coating. They are made up from a tubular trough equipped with at least one inlet and outlet spout, a welded flange at each tube end, helicoid screw flighting welded on a center pipe with coupling bush at each end, two end bearing assemblies complete with self-adjusting shaft seal (one of the bearing assemblies is integrated into the drive unit), and a number of intermediate hanger bearings depending on the overall length. ES Screw Conveyors and Feeders are equipped with a gear motor that suits the application.

Function

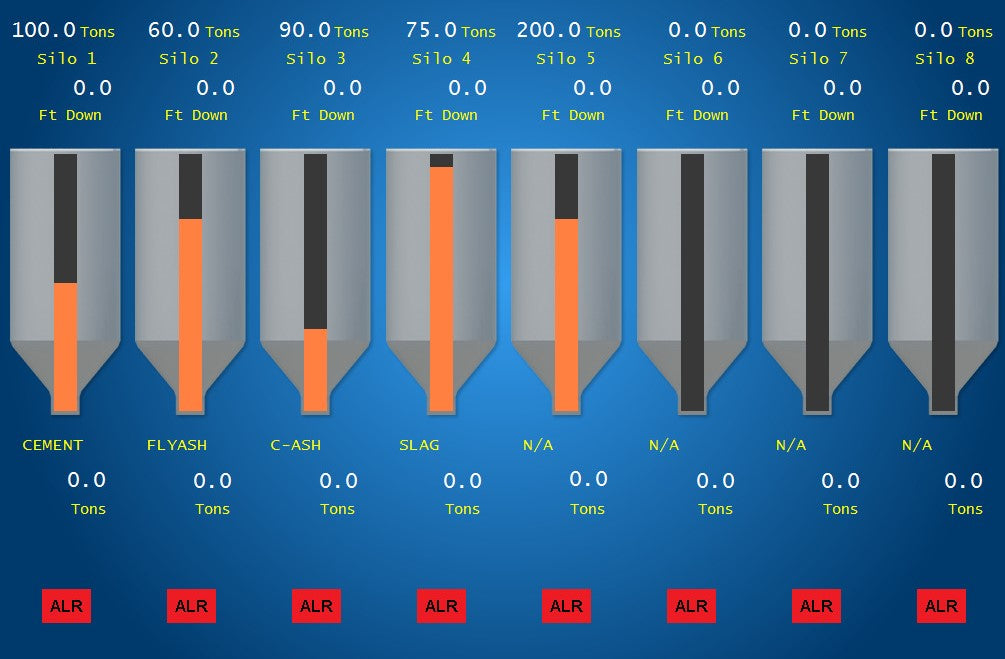

ES Screw Conveyors and Feeders are used for conveying or feeding cement and materials similar to cement mainly in concrete batching plants but also in other building materials processing plants.

Features

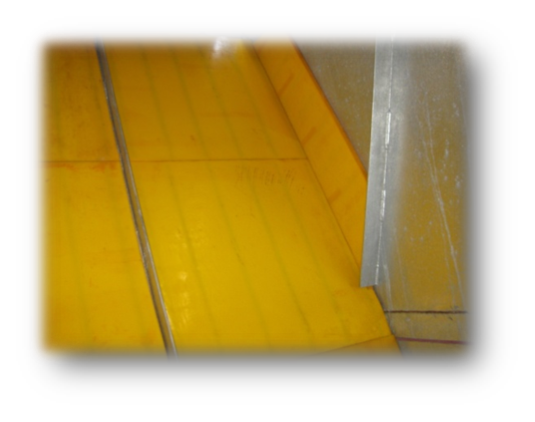

- Primed and Painted with a High Finish Enamel Paint as Standard

- 5 outside tube diameters

- Outside tube complete with welded end flanges, one inlet, one outlet, inspection hatch beneath the first inlet and beneath each intermediate hanger bearing

- Tubular housing in standardized flanged sections with one section made to measure

- Helicoid screw flighting welded on center pipe

- End bearing assemblies complete with self-adjusting shaft seal

- Splined shaft couplings

- Lifting eyelets on each tube section

- Standard flange-mounted electric motor

- Maintenance-free aluminum-cast intermediate hanger bearings with self-lubricating slide bushes

- Compact design and overall dimensions

- Reduced number of components and spare parts

Benefits

- Durable

- Maintenance-free

- Quick installation due to universal inlet and outlet spouts

- Optimum price-performance ratio

Options

- Different types of inlet and outlet spouts

- Additional inspection hatches

- External supports

- Drive unit at outlet end

- Selection of gear ratios resulting in different feed rates

- CEMA V finish available